Technical Cleanliness Microscopes

Nov 2nd 2022

What is Technical Cleanliness?

Contamination control is a key issue in manufacturing and production. Technical cleanliness is important for the automotive, aviation and space industry, manufacturers of oils and lubricants, and medical product manufacturers. The functionality and lifetime of certain products is directly linked to the degree of surface contamination with residual dirt particles. The reduction and avoidance of malfunction and breakdown is one of the driving demands in technical cleanliness of technical parts. Technical cleanliness testing measures the particulate contamination on product surfaces. Cleanliness testing of technical products helps to improve product quality, extends product lifetime, and improves the quality assurance of the manufacturing process. Cleanliness testing of medical products helps decrease the risk of repulsion reactions, and improves tissue compatibility.

Contamination control is a key issue in manufacturing and production. Technical cleanliness is important for the automotive, aviation and space industry, manufacturers of oils and lubricants, and medical product manufacturers. The functionality and lifetime of certain products is directly linked to the degree of surface contamination with residual dirt particles. The reduction and avoidance of malfunction and breakdown is one of the driving demands in technical cleanliness of technical parts. Technical cleanliness testing measures the particulate contamination on product surfaces. Cleanliness testing of technical products helps to improve product quality, extends product lifetime, and improves the quality assurance of the manufacturing process. Cleanliness testing of medical products helps decrease the risk of repulsion reactions, and improves tissue compatibility.

What Industries Use Technical Cleanliness?

- Automotive Industry, NEV

- Medical Technology Manufacturing

- Additive Manufacturing

- Aerospace Aviation and Space Industry

- Manufacturers of Oils and Lubricants

What is Technical Cleanliness Looking For?

- Technical Cleanliness for Components: Metallic shiny particles (machining chips, metal scraps and flakes), non-metallic shiny particles (laquer, plastic, and abrasive residues) , fibers.

- Technical Cleanliness of Oil: Is the used oil clean? What types of contaminants are in the oil? Where are contaminants originating from? Is the machine degrading abnormally?

- Technical Cleanliness for Medical Devices: Syringes, implants, etc. all need to be produced in an extra clean production environment for medical use.

- Technical Cleanliness in Assembly: Testing of environmental conditions such as air or working benches.

What are Possible Contamination Sources and Applications?

|

|

|

|

|

| Particles Between Moving Parts |

Particles Between Electrical Contacts |

Particles in Injection Nozzles |

Particles in Syringes and Implants |

Particles in Oil and Lubricants |

What Types of Particles are Found in Technical Cleanliness Testing?

- Hard Particles = Metals, Minerals, Ceramics

- Soft Particles = Fibers, Polymers, Cellulose

- Electrically Conducting Particles = Steel, Copper, Aluminum

What are the Inspection Standards for Technical Cleanliness?

Technical Cleanliness Standards:

- ISO 16232 - Cleanliness of Road Vehicles, Components and Systems

- VDA 19.1 - European Standards: Inspection of Technical Cleanliness, Particulate Contamination of Functionally Relevant Automotive Components

- VDA 19.2 - European Standards: Technical Cleanliness in Assembly - Environment, Logistics, Personnel and Assembly Equipment

Oil Cleanliness Standards:

- ISO 4406 - Hydraulic fluid power — Fluids — Method for coding the level of contamination by solid particles

- ISO 4407 - Hydraulic fluid power — Fluid contamination — Determination of particulate contamination by the counting method using an optical microscope

- NAS 1638 - replaced with AS 4059

- SAE AS 4059 - Aerospace Cleanliness Classification for Hydraulic Fluids

- DIN 51455 - European Standards: Liquid petroleum products - Determination of particle number and particle size in oils

Cleanliness of Manufacturing Medical Devices:

What are the Technical Cleanliness Microscope Options?

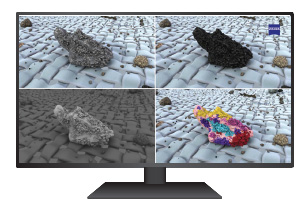

Cleanliness testing involves taking a particle membrane filter from a cleaning cabinet or other particle extraction method and placing it under the microscope for technical cleanliness analysis. The chart below details the technical cleanliness microscopes available along with the particle size they can view.

| ZEISS Stereo V8 Technical Cleanliness Microscope | ZEISS Axioscope 7 Technical Cleanliness Microscope | ZEISS AxioZoom V16 Technical Cleanliness Microscope |

|

|

|

| Particle size ≥ 15µm | Particle size ≥ 50µm | Particle size ≥ 5µm |

| Standard Analysis | Standard Analysis | Advanced Analysis |

| Identify fibers and differentiate between metallic shiny and non-shiny particles for standard cleanliness testing applications. | Automation for your standard analysis with fully motorized axes of motion for automated imaging and height measurement. |

Perform accurate and repeatable analyses with this fully automated digital zoom microscope that supports rapid large field scanning. |

Technical Cleanliness Software

Each of the technical cleanliness microscope systems includes technical cleanliness analysis software. The software supports the standards for component cleanliness, oil cleanliness, and cleanliness of medical products.

Each of the technical cleanliness microscope systems includes technical cleanliness analysis software. The software supports the standards for component cleanliness, oil cleanliness, and cleanliness of medical products.

The software includes pre-configured automatic workflows as well as 5 different job templates, each suited for a different type of technical cleanliness analysis.

Have questions about Technical Cleanliness analysis or which Technical Cleanliness Microscope is right for you? Contact Microscope World at 800-942-0528.