Filter Patch Inspection Explained

Sep 27th 2018

So, you work in a facility which has a lot of lubricated machinery operating and you want to do some quality control work, just to make sure the large (and expensive!) machines are working well and not wearing out. Basically, you want to know if there are potentially harmful particles moving around within the machinery.

Spectrographic and automated particle counting analysis programs are highly technical instruments that can identify the elements of particles floating around in your machines. However, they often fail to distinguish harmless fibers and metals from problematic ones. For this there is simply no replacement for visual inspection by trained personnel.

A filter patch inspection microscope is the perfect tool to visually inspect for harmful particulates within your machinery lubrication. After filtering fluid through a filter patch using whatever combination of funnels, oil sampling vacuum pumps, and solvents you prefer, you place the filter under a stereo zoom microscope with top and bottom illumination and take a look.

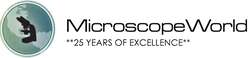

Above we have an image of a filter patch that was placed under the filter patch microscope at 50x magnification using only the bottom transmitted light. Notice that the particles vary in size, shape, and density. There are fibers evident at the top and the left side, as well as dark, somewhat indistinct solid particles scattered throughout.

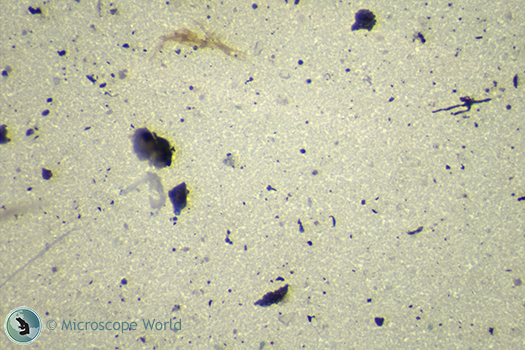

When we switch over to the top (reflected) light only, many of the dark, indistinct objects shine, revealing them to be metallic. The optimal lighting is usually a combination of the top and bottom lights, so that you get the reflected light shining on metal, while having the image bright enough so as not to strain the technician's eyes.

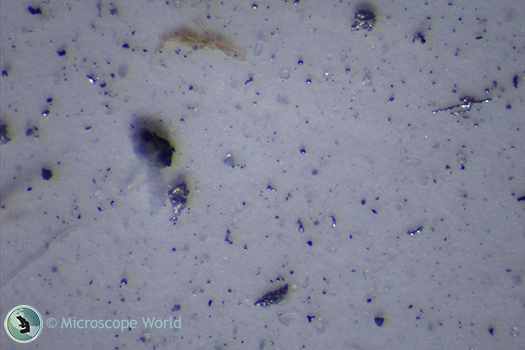

The image above shows a filter patch under the filter patch inspection microscope using a combination of both top and bottom illumination.

At this point, the trained technician’s experience kicks in. What does the presence of metallic particles mean for the overall health of the machinery? Do fibers indicate wearing down of components? Is there a particle size threshold that spells danger? By using the visual information gained from the filter patch microscope system, quality control staff can start troubleshooting.

If you have questions regarding a filter patch inspection microscope or the process of analyzing filter patches under the microscope, contact Microscope World and we will be happy to help.