Viewing Polymers under the Microscope

Nov 6th 2017

In the chemical industry and when manufacturing plastic goods examining materials under the microscope is of utmost importance. Polymers can be examined in their primary forms, or once they have been made into industrial and consumer products. Plastic parts and structural components play a large role in industries including aerospace, automotive, construction and medical equipment.

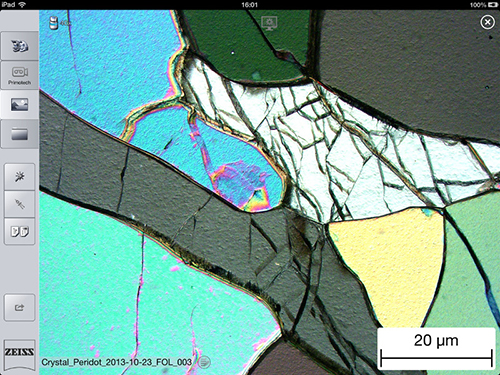

Crystallization of Polymers: Crystal morphology affects the mechanical properties of a polymer, but can also determine its biodegradability and bio-compatibility. A solid understanding of polymer crystallization is required in order to control the polymer's micro structure and achieve the desired properties. Upright polarizing microscopes are used to inspect final materials, and also monitor crystal growth. Typical items of interest include viewing polymer morphology, structure, crystallinity, spherulites and the onset of crystallization temperature. This is an image of crystals captured with the Zeiss Primotech Materials microscope using the Matscope digital App.

This is an image of crystals captured with the Zeiss Primotech Materials microscope using the Matscope digital App.

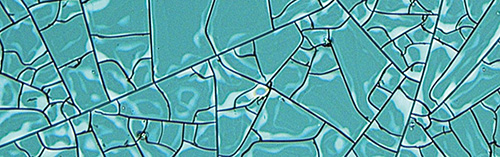

Failure Analysis: Polarizing microscopes are also used to view failures in the manufacturing process of parts and products. The surface structure of fracture planes provides information on the cause of a failure, defects, origin of cracks and more. Once a polymer is deformed, it will show bi-refringence due to internal rearrangement of the molecules. This phenomenon is used to study stresses in polymer materials, possibly in mechanical parts that have been exposed to strain, with the help of polarized light microscopy. A polymer that has been mechanically sculpted during production, such as plastic that was formed using injection molding, becomes directionally dependent, and can be viewed with a polarizing microscope. This image is polymers captured under a polarizing light microscope.

This image is polymers captured under a polarizing light microscope.

Surface Topography: For any applications where you need to observe the surface topography of a plastic part or measure roughness parameters, confocal microscopy is the best technique. With the aid of fluorescence, polymer blends can be studied. In addition, confocal microscope techniques detect non-homogeneities and defects underneath the surface, such as cavities, pores and inclusions.

Sample Preparation: Electron microscopy is used for sample preparation such as milling, abration and generally structuring the material for light microscopy.

In the chemical industry and manufacturing arena polymers are viewed under the microscope when viewing crystal morphology, spherulites, surfaces of fracture planes, process control, failure analysis, roughness, strain, quantitative and qualitative micro-structure analysis and when viewing interference patterns.

If you have questions regarding the use of polarizing light microscopes, confocal microscopy, or electron microscopy contact Microscope World.